Engineers at University of Wales Trinity Saint David (UWTSD) have been involved in the rapid development of a highly efficient 3D printed jet Venturi based respiratory support system.

The project team came together following calls by Welsh Government and industry to develop rapidly manufactured CPAP solutions to aid SARS-CoV-2 patients with breathing difficulties.

The team (assembled a little over a month ago), is being led by Mr Graham Howe and Mr Luca Pagano from MADECymru along with Professor Peter Charlton, Mr Richard Morgan and Mr John Hughes from the School of Engineering. The team assembled staff with experience in the fields of engineering, physics and rapid manufacturing, also drawing upon the expertise of John Hughes – one of UWTSD’s postgraduate engineering students to carry out, vital, computational modelling.

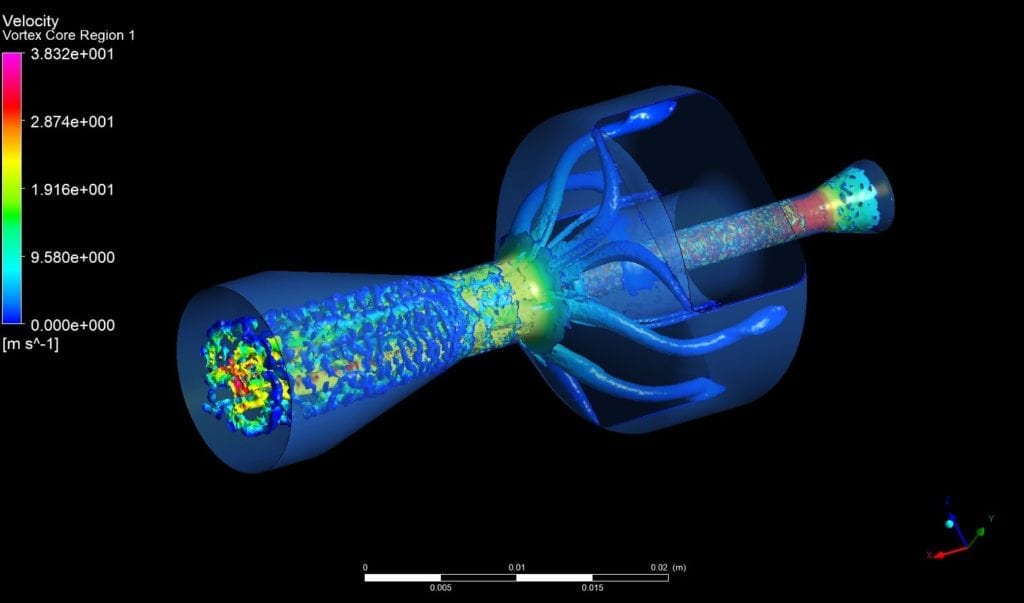

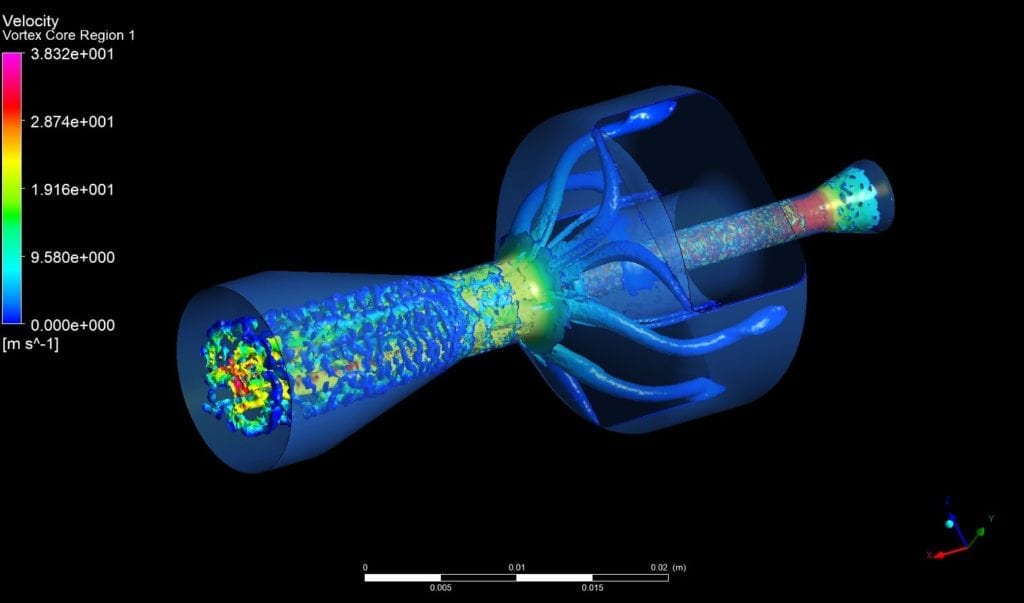

The solution is the result of assessing and revisiting Post-Graduate project work undertaken within the School of Engineering (UWTSD), which outlined the potential of the Venturi effect in gas therapy applications. Following consultation with numerous healthcare professionals and industry groups, the primary challenge for SARS-CoV-2 gas therapy was identified to be the high level of oxygen utilisation. This high demand is due to number of active patients and consequent low oxygen availability due to infrastructure overload and losses caused by inefficient, existing appliances. Hence, oxygen consumption being the main parameter controlled in the whole optimisation/modelling process.

The Venturi effect, mostly found in so-called Venturi jet ejectors (used in hydraulic/gas systems) can provide entrainment of a secondary fluid or gas as a consequence of an optimised nozzle geometry from which a motive fluid flows. Essentially, this science, when combined with the right physical geometries allows patient delivery of a controlled pressurised range of mixtures of air / oxygen by simply connecting the oxygen line available in hospitals; with no electric supply required.

The first experimental validation was undertaken in Singleton Hospital (Swansea), on May 6. The tests carried out, gave the team the opportunity to compare the performance of physical prototypes to the analytical and computational models previously used to design and optimise the system geometry. This validation test indicated that the system is able to deliver 40% and 65% FiO2 (Fraction of Inspired Oxygen) respectively at 2 and 6 litres per minute of oxygen volume flow. The results of these tests have proven that such a configuration is set to out-perform most of the available CPAP (continuous positive air pressure) devices and Venturi systems showing a potential to deliver 24%FiO2 with less than 1 litre per minute of oxygen volume flow.

The main ethos of the team was to develop a solution which is freely accessible to health authorities from every country in need, therefore, from a manufacturing perspective, the team has already developed a number of different bespoke solutions. A number of different assembly options are possible, which can comprise off the shelf medical circuit connectors or a fully 3D printed system (this is the prototype currently undergoing tests). All of these options interface with the patient using off the shelf, readily available, low cost, adjustable anaesthesia mask held in place by a 3D printed brace. The 3D printed fully functional prototype as it stands, could potentially be a download plug and play device, anywhere in the world. All at a cost of £5/6 worth of materials.

Being a life aid, the system is able to interface with standard PEEP Valves and Viral Filters to protect both patients and workers.

The successful completion of pre-production prototypes was made possible thanks to the expertise and assistance in additive manufacturing offered by CBM and the CT-Radiography NDT&E tolerance deviation analysis of TWI Technology Centre Wales.

The full system is currently undergoing extensive failure modes and effects analysis and further testing is being carried out.

Graham Howe Principal Research Fellow (Advanced Manufacturing) at UWTSD said: “It’s been a challenging, yet rewarding experience, working with a multi-disciplinary team of Engineers from the University, each bringing their own expertise to drive the development of this device. We have also had superb support from our long standing industrial partners, without whom, we couldn’t have completed this work. This project has shown what can be achieved when organisations join forces for the national good and we hope that this device will help support the fantastic work the NHS frontline staff are doing to treat Covid-19 patients.”

Leave a Reply

View Comments