The eyewear industry is a key culprit for plastic waste and the production of carbon emissions across the globe. With over 4 billion adults now wearing glasses across the globe, brands are constantly churning out new specs and styles to meet the growing demand for trendy eyewear.

As luxury brands continue to use “detractive manufacturing” techniques to speed up production times, over 65-70% of the acetate plastic used during production is disregarded.

Moving into 2023, this ever-growing market has an eco-friendly journey on its hands. The question is, could technology be the answer the industry has been looking for? On the back of a 3D printing boom in the manufacturing sector, eyewear giants are striving for sustainability as they introduce automation to their production process.

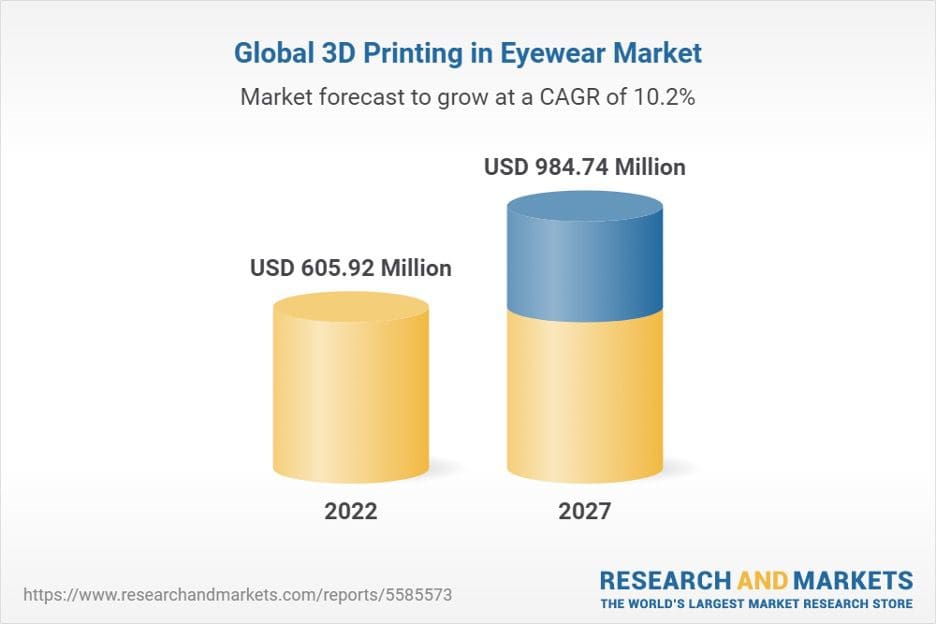

(Image Source: Research & Markets)

According to experts from Research & Markets, global 3D printing in the eyewear market is expected to grow at a CAGR of 10% in the next five years after $605 million was invested in automation in 2022.

In a new era of ‘additive manufacturing’, AI-driven automation could reduce plastic waste by only consuming the material needed for production.

Stick with us as we navigate what a sustainable future could look like in the eyewear industry and reveal some pioneer brands investing in automation in 2023.

Wires Glasses

The first brand spearheading a sustainable future of eyewear production is Wires Glasses. The London-based luxury brand has turned to 3D printing in an attempt to go green. Embracing the powers of automation, Wires aims to reduce the length of its supply chain and use an AI-driven printing system that leaves zero waste during the production process.

“We are always looking at ways to improve our supply chain: to minimise any negative impacts and increase positive impacts,” says Wires’ CEO Lily Cole. “We believe that in this critical moment in time, companies – and the people who support them – have a critical role to play at the forefront of driving more sustainable and fair practices within supply chains. We hope to demonstrate that sustainability is not only possible – but that it can be beautiful too.”

Better still, Wires have also invested in sustainable materials to make their classic eco glasses, such as their Earth Heart and Half Moon frames.

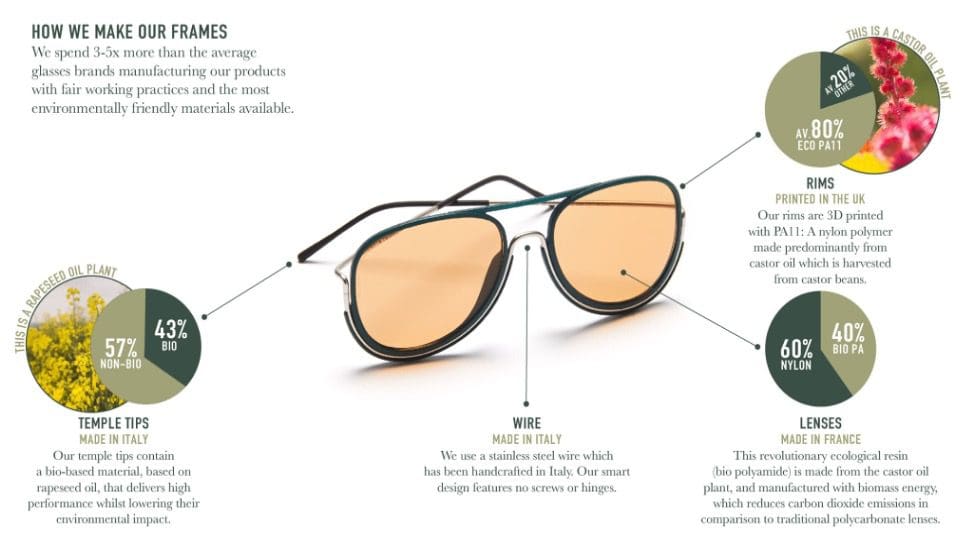

(Image Source: Wires Glasses)

Manufactured using bio-nylons, Wires aim to create luxury eyewear without using petroleum-based plastics, which are responsible for 4% of global oil usage.

Lowercase Eyewear

Lowercase Eyewear has also invested in automation in an attempt to improve its sustainability. Rather than opting for 3D printing, the US-based brand has introduced a ‘Robotiq gripper on a UR5 collaborative robot arm’ to their production line, which aims to reduce manual labour and speed up the supply chain.

With a quicker turnaround and the need for fewer manual workers, Lowercase saves on energy costs associated with manufacturing and produces high-quality eyewear using robotic automation.

“This automation is important for us. Eyewear production is a very labour-intensive process, and we are such a small team that any improvement we can make to our efficiency is huge,” said Lowercase CEO Gerard Masci. “Having a product that allows me to sit at the computer and work on design or go work on the more labour-intensive stuff that can’t be done by machines is a big plus for us.”

With 17 different styles of eyeglasses in their current online store, this NYC brand believes that investing in an AI-driven program gave them new abilities to quickly change up designs and adapt the production process on the go, reducing waste and saving time.

Fitz Frames

Who said choosing your next pair of specs can’t be fun? The US-based eyewear brand Fitz Frames has its own AR-infused app that allows customers to take a picture of their face and digitally create a pair of glasses customised to their needs.

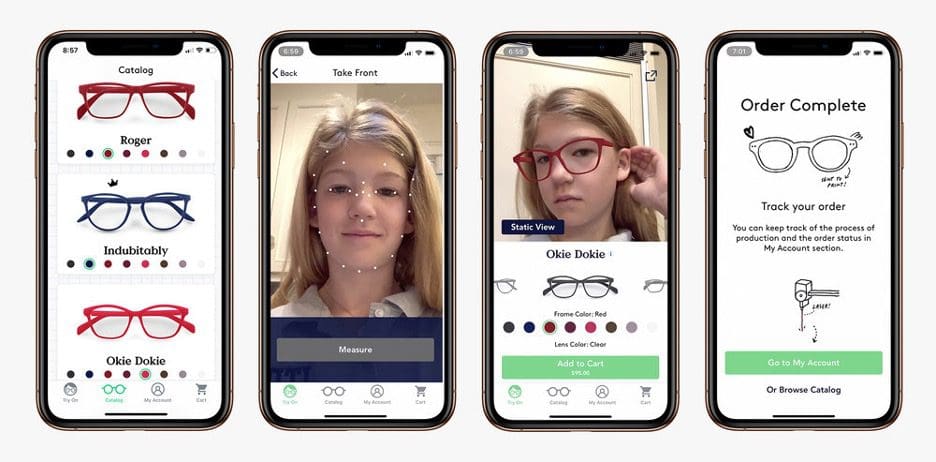

(Image Source: Fitz Frames)

Each facial scan is then sent automatically to Fitz’s warehouse and 3D printed in the exact shape and design. Using a 3D printer, the brand ensures that its production process “pushes the limits of part performance, sustainability, and automation all while decreasing manufacturing complexity.”

“We proudly design and manufacture our glasses in the USA. Each pair is built at our facility in Youngstown, Ohio,” says founder Heidi Hertel. “We don’t waste material during manufacturing, and we don’t ship out our glasses with plastic wrap and unnecessary materials.”

Pulling away from traditional manufacturing methods, Fitz aims to position the consumer at the forefront of their brand. As technology opens up doors for new levels of personalisation, consumers will be less likely to return frames, reducing the amount of plastic waste the industry creates from spectacle throwaways.

A greener future for eyewear brands?

The eyewear industry is constantly evolving. With sustainable material alternatives and a rise in supply chain automation, we could see a greener future for frame makers across the globe.

According to Millmead Optical Group’s CEO, James Conway, a new push for industry-based sustainability comes from both the consumer and the brands aiming to make it big.

“It is a hybrid of consumers asking questions and wanting to know how their products are made, what they were made of, and expecting more,” Conway claims. “From the point of view of the manufacturers and suppliers, we also have a responsibility, and we have to think about the future impact our businesses are having on the environment for everybody.”

As we see 3D printing take off, robotics used more frequently, and even AI-driven personalisation technology introduced, there’s no excuse for hanging back from technological aids in 2023. If eyewear brands want to rival industry giants, automation is a manufacturing must-have.