You are about to sink conduits into concrete, and the stakes feel permanent. Getting the layout right now can spare you chiselling headaches later. Think through load paths, moisture, and future access before the mix even pours. For today, you are pacing rebar grids, marking box heights, and picturing walls before they rise.

Substation Building Essentials

Modern concrete substations require early coordination between civil and electrical teams, because embedded conduits, grounding grids, and transformer pads become permanent once the pour cures.

- Choose a configuration early: Single-busbar, breaker-and-a-half, or ring-bus schemes affect slab size, column spacing, and the number of under-slab conduits required for future flexibility.

- Respect utility standards: The UK’s National Grid guidelines illustrate Security and Quality of Supply requirements that drive bay spacing, earthing meshes, and fire zoning.

- Plan equipment weights: GIS switchgear loads differ from traditional AIS yards; reinforce footings under heavy gas-insulated enclosures to prevent cracking that can propagate through the deck.

- Integrate drainage channels: Sloped floors and polymer trench covers divert wash-water and rain away from energised gear, limiting corrosion and moisture-induced partial discharge in joints.

- Embed spare conduits: Extra sleeves save chiselling later when grid-scale batteries or STATCOM units inevitably require additional medium-voltage feeders. Securing a crew with emergency power help is far cheaper than jack-hammering cured concrete.

Finishing slabs with non-conductive hardeners reduces step-potential risks, while colour-coded epoxy coatings help maintenance crews visually separate high-voltage bays from control corridors.

High-Voltage Foundation Design

Concrete foundations supporting 132 kV and above endure thermal, dynamic, and environmental stresses; designing them well prevents dielectric breakdowns and costly outages later.

Soil resistivity surveys

Start with Wenner four-pin tests to map resistivity. Low values permit shorter ground rods, whereas rocky sites need deep electrodes bonded to rebar mats.

Rebar continuity

Specify welded rebar couplers at grid intersections, ensuring an unbroken equipotential plane that safely dissipates fault currents without arcing between bars and conduits.

Vibration considerations

Transformer energisation produces a 100 Hz hum on 50 Hz systems; isolating pads with neoprene layers and properly anchored inertia blocks prevent micro-cracks that invite water ingress and corrosion.

Thermal mass benefits

A thick plinth acts as a heat sink, buffering oil-filled equipment from temperature swings and reducing expansion-contraction cycles that strain bushings and gaskets.

Cable Trenches and Routing

Keeping cables organised, accessible, and protected beneath reinforced concrete requires thoughtful trench geometry, separation rules, and future-ready capacity planning.

- Adopt tiered duct banks: High-voltage feeders occupy the bottom tier, control cables the top. This minimises induced voltages while simplifying troubleshooting activities.

- Maintain bend radii: Deep trenches tempt tight sweeps; use factory elbows or PVC-coated rigid steel to honour manufacturer minimum bend requirements, preserving insulation integrity.

- Allow ventilation slots: Heat from full-load currents dissipates through grated covers; stagnant hot air accelerates insulation age and derates ampacity unexpectedly.

- Label every pull rope: Permanent stainless tags referencing drawings expedite future cable additions and reduce the risk of mistakenly energising dormant spares.

- Reference best-practice guides: RBT Automation’s industrial cable layout guide offers pragmatic spacing, segregation, and redundancy tips transferable to utility sites.

Finish trenches with chamfered edges that resist chipping from traffic, and specify anti-rodent stainless mesh where telecontrol fibres share the same pathway.

Oil Containment Solutions

Dielectric oil spills threaten soil and groundwater; concrete structures must incorporate proven containment strategies that outlast equipment life cycles.

- Integrate sump liners: Spray-applied polyurea inside concrete pits creates a seamless membrane resisting transformer oil, acids, and ultraviolet degradation for decades.

- Design gravity separators: Sloped floors channel leaks toward valved chambers where hydrophobic filters let stormwater escape while trapping hydrocarbons for safe disposal.

- Account for fire water: Fire-suppression runoff volume often exceeds containment wall height; oversize berms or install automatic weirs that seal when oil is detected.

- Provide inspection ports: Stainless access tubes enable periodic visual checks and facilitate vacuum extraction of small accumulations before they reach discharge thresholds.

- Select modular barriers: Prefabricated composite panels from specialty vendors clip onto existing foundations, upgrading legacy yards without disruptive demolition work.

Combining these measures with routine infrared scans of bushings significantly reduces environmental liability and outage-related financial penalties.

Block Wall Options

Concrete or cinder block walls partition equipment rooms, shield occupants from arc-flash, and support conduit runs, so their detailing directly affects electrical reliability.

- Choose wall type wisely: Solid concrete units absorb arc energy better than hollow blocks, though filled cavities with grout and rebar offer near-equivalent protection.

- Embed conduit chases: Cast-in plastic sleeves preserve wall integrity; chiselling later introduces stress points that propagate cracks under seismic loading.

- Add moisture barriers: Elastomeric coatings on the cable side prevent dampness wicking into terminations, maintaining insulation resistance above design levels.

- Coordinate anchor placement: Pre-install Unistrut inserts so electricians can mount trays without drilling that might intersect reinforcement or compromise fire ratings.

- Ensure aesthetic durability: A lightly sand-blasted finish hides scuffs from carts and ladders, extending repaint intervals and lowering maintenance costs.

Thoughtful wall layouts also create clear egress routes, reducing evacuation time in the unlikely event of an internal arc fault or gas leak.

Building Code Compliance

National and local electrical codes dictate conduit fill, receptacle spacing, and grounding requirements; concrete projects must embed those rules long before inspection day.

Understand inspection triggers

Structural pours covering conduits require sign-off beforehand. Missing documentation forces expensive X-ray scans or destructive coring to prove compliance later.

Reference residential parallels

The Home Depot’s concise residential code summary illustrates spacing logic transferable to industrial sites, highlighting why overfilled boxes fail acceptance tests.

Document every deviation

If field conditions force changes, annotate drawings immediately; inspectors respect transparent change logs aligned with stamped engineering judgements.

Schedule incremental walk-throughs

Invite authorities at slab, rough-in, and energisation stages; phased approvals limit punch-list surprises and keep commissioning targets intact.

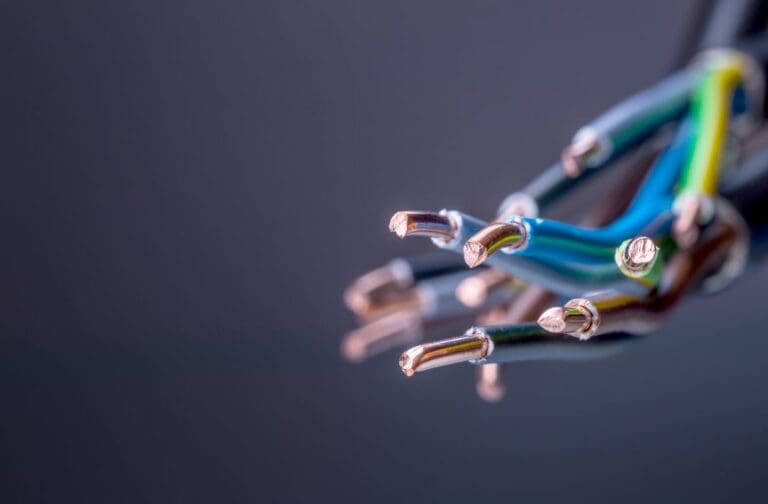

Durable Material Selection

Choosing conductors, insulators, and protective finishes that coexist peacefully with alkaline concrete chemistry keeps circuits performing flawlessly for decades.

Copper versus aluminium

Copper’s superior creep resistance suits bolted bus connections, whereas modern AA-8000 aluminium saves weight and cost when properly terminated with oxide-inhibiting compounds.

Insulation compatibility

Cross-linked polyethylene withstands concrete’s moisture better than thermoplastic PVC; specify XLP for feeders cast into slabs to avoid water-treeing failures.

Corrosion-resistant hardware

Hot-dip galvanised anchors last longer than plain steel but consider 316 stainless where de-icing salts or coastal chlorides accelerate oxidation.

Fire-retardant coatings

Intumescent paint on tray supports buys critical evacuation minutes, meeting NFPA 850 recommendations for substation structural elements.

Core Electrical Design

A robust design philosophy aligns protective relays, conductor sizing, and earthing networks with the immutable realities of concrete mass and geometry.

Short-circuit forces

Concrete-embedded supports must resist electromagnetic forces exceeding 40 kN during faults; finite-element models guide anchor spacing and dowel embedment depths.

Voltage drop budgeting

Long conduit runs through slabs gain resistive heat; upsizing conductors or adding sectionalising cabinets mitigates losses and eases future capacity upgrades.

Separation from control circuits

Maintain 300 mm clearance or grounded metallic barrier between power and instrumentation conduits, limiting induced noise in fibre media converters and IED inputs.

Arc-flash reduction

Installing remote racking systems and maintenance-mode settings on breakers lowers incident energy, protecting staff working near heavy concrete cells.

Concrete Load Pathing

Understanding how electrical loads translate into physical forces within concrete helps engineers prevent cracking around conduit clusters and embedded boxes.

Conduit grouping strategy

Stagger large conduits vertically rather than side by side, retaining adequate aggregate coverage to maintain compressive strength and minimise void formation.

Expansion joint alignment

Place joints away from high-current raceways; cyclic movement can abrade insulation or shear conductors if poorly sleeved across gaps.

Panel anchorage

Mount switchboards on plinths isolated from structural columns; differential settlement then cannot twist busbars or misalign bolted joints.

Seismic reinforcement

Add hairpin steel around wall penetrations; these ties distribute shear forces and keep knockout edges from spalling during earthquakes.

Concrete Synergy

You now possess the critical checkpoints for integrating electrical systems with resilient concrete. Apply them methodically, verify each load path, and document every embed. When uncertainties arise, consult a qualified contractor or refer to guidance from The Local Electrician; by doing so, you protect performance, budgets, and future maintenance windows.